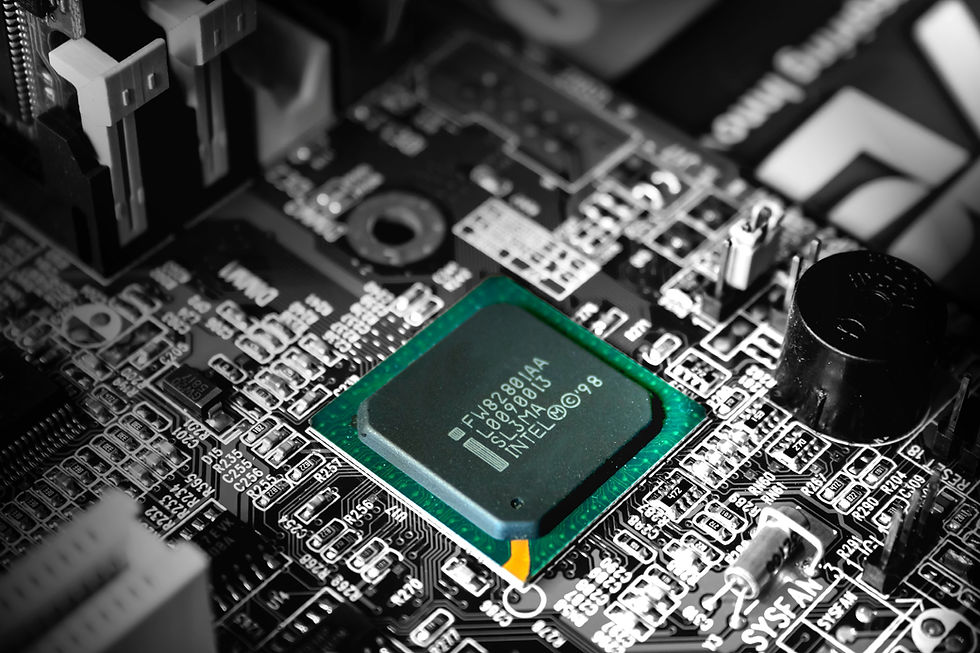

If you are even a tiny bit into the world of tech, you probably have heard about something called the chip shortage. Well, you do not have to worry about your favourite potato chips being out of stock yet. The chip shortage that we are talking about here is the processors that run all kinds of electronics and equipment.

Before trying to explain why and how this is happening, let us see its effect on our lives:

Wondering why all electronics in your wishlist, ranging from smartphones and laptops to home appliances like refrigerators and dishwashers, have all become so expensive? You could blame the government for increasing taxes and import duties, but there is something even more significant than that causing all of this.

Planning to buy a car, but the waiting list is as long as a year looks scary to you? It is not the manufacturers' fault, but something you wouldn't even have thought of is causing you all the trouble.

These are just some of the problems right now out of many caused by the global chip shortage, and it is only getting bigger. Partick Gelsinger, CEO of Intel, says that this massive silicon shortage will stay for as long as 2023 and is not going away any sooner. So how did this all happen in a few months?

How it all started

When the COVID-19 pandemic hit the world in 2020 and countries were imposing lockdowns on all commercial activities, companies like TSMC (Taiwan Semiconductor Manufacturing Company) and Samsung that manufacture processors decided to slow down processor manufacturing as demands plummeted. Companies like Toyota and General Motors cancelled their processor orders as their sales too dropped significantly. (P.S: A modern car can require as much as 50 CPUs) But, during the lockdown, the demand for electronic products like smartphones, tablets and laptops exploded. The only problem is that these processor manufacturing centres (fab-labs) could only function with less than half the capacity. Things got even worse when things started to open up, and the demand for several other electronics and automobiles also surged through. When these companies who had previously cancelled their orders wanted to re-order, they now had to stand in the long queue of companies bidding to place massive orders. As demands were reaching almost the same levels as 2019, it became more and more difficult for companies to manufacture. The situation became quite tense when Taiwan had to face a never seen before drought as the bulk of the water went into the production of silicon, used in processors. Since then, the problem has not gotten a solution.

But why?

You could be thinking, "well, to fix this problem, just make more manufacturing setups and increase production". But, creating fab-labs for processor manufacturing and producing silicon is a multi-billion dollar investment a company has to make and then investing in supply chain systems can ruin companies. Processor manufacturing is something only very few companies can do today, as it requires a lot of research and development and minute manufacturing. TSMC, Samsung and Intel are currently the only major semiconductor manufacturing companies. All of this is leading smartphone launches to be cancelled, like the dissolution of Samsung's Note Series and the delayed launch of the giant's S21 FE smartphone. The increased cost of electronics overall due to massive supply chain issues has become a bummer.

What to do now?

It is now imminent that this shortage is not going away as early as we hoped it would, so we don't have a choice but to buy our required electronics at the increased rates. Companies like Samsung Semiconductors has announced that it will be tripling their production capacity to combat this shortage. TSMC has announced to invest $100 billion over three years in the United States to set up Fab Labs. The Indian Government has also announced a $1 billion reward for companies to indigenise processor manufacturing in India.

Comments